EPS mold, also known as Styrofoam mold, is a type of molding process used to create custom-shaped parts or components. It utilizes expanded polystyrene foam as the primary material.

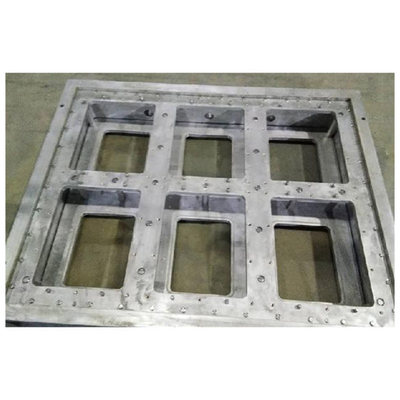

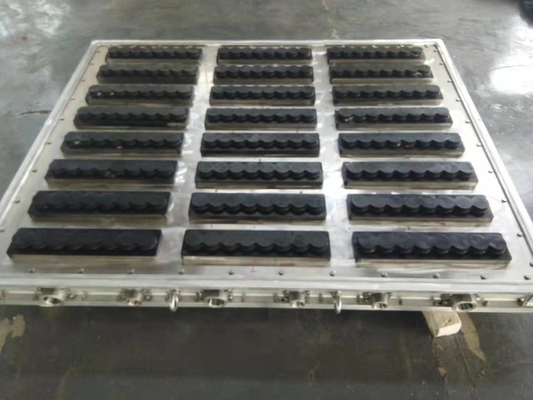

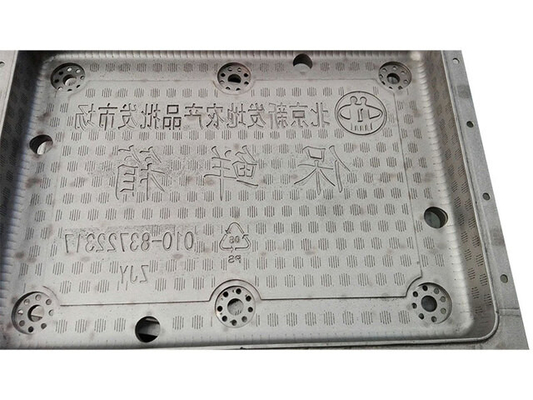

Mold Fabrication:

A mold is created from EPS foam blocks or beads using hot wire cutting, CNC machining, or manual shaping.

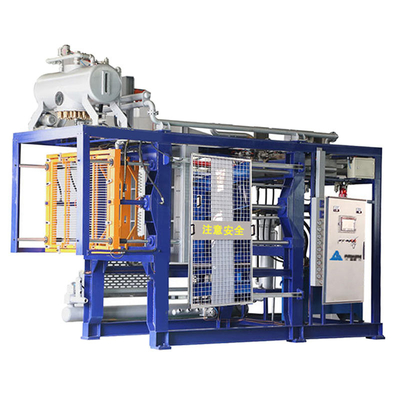

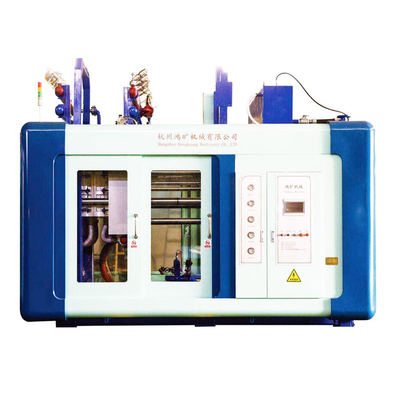

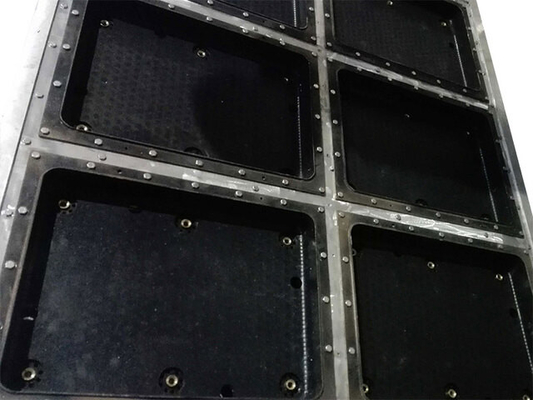

Bead Expansion and Molding:

Polystyrene beads are heated and expanded inside a mold cavity.

Curing and Demolding:

The expanded polystyrene part is allowed to cool and stabilize within the mold.

The key benefits of EPS mold include:

Lightweight and insulative properties of the polystyrene material

Ability to create complex, custom shapes and geometries

Cost-effective production process for low to medium volume parts

Ease of mold fabrication and modification

Recyclability of the EPS material

EPS molding is commonly used in a variety of industries, such as:

Packaging (protective casings, inserts, and cushions)

Building and construction (insulation, architectural elements)

Automotive (interior components, bumper cores)

Marine (flotation devices, boat hulls)

Aerospace (structural components, thermal insulation)

The versatility and cost-effectiveness of EPS molding make it a popular choice for many product design and manufacturing applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!