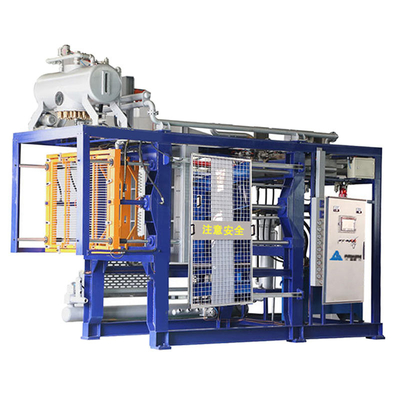

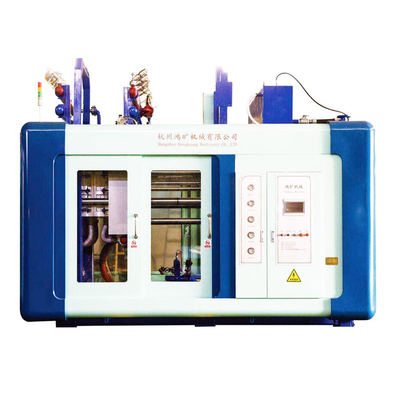

EPS With Elevating Device Auto Block Molding Machine

Main features :

1, Performing fully automatic,semi-automatic,middle starting and manual operating mode.

2, Using hydraulic system mold clamping,stable and reliable.

3, The main intake of steam control valve is pneumatic valve,good sealing,and long life.

4, Using the programmable control with color touch screen control,easy to operate.

5, Automatic feeding,convenience and high efficiency.

6, The main components(CPU template,touch screen,etc.) all use international and domestic brands.

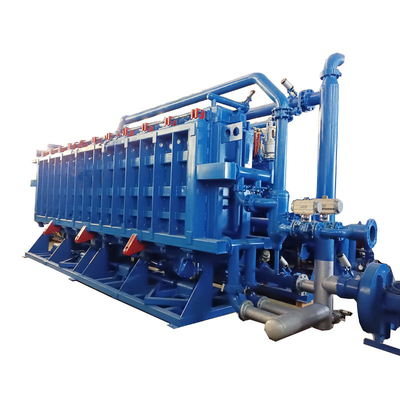

| Item |

Unit |

PSBM300AC |

PSBM400AC |

PSBM600AC |

PSBM800AC |

| Mould Cavity size |

mm |

3060X1240X1030 |

4080X1240X1030 |

6100X1240X1030 |

8120X1240X1030 |

| Block Size |

12g/L |

3000X1200X1000 |

4000X1200X1000 |

6000X1200X1000 |

8000X1200X1000 |

| Steam Inlet |

mm |

DN100 |

DN150 |

DN150 |

DN200 |

| Steam Consumption |

kg/cycle |

50-70 |

60-90 |

100-130 |

120-170 |

| Steam Pressure |

Mpa |

0.8 |

0.8 |

0.8 |

0.8 |

| Compressed Air Inlet |

mm |

DN40 |

DN40 |

DN40 |

DN40 |

Compressed Air

Consumption |

m³/cycle |

0.4-0.6 |

0.6-0.8 |

0.4-0.6 |

0.4-0.6 |

Compressed Air

Pressure |

Mpa |

0.6 |

0.6 |

0.6 |

0.6 |

| Cooling Water Inlet |

mm |

DN40 |

DN40 |

DN40 |

DN40 |

| Cooling Water Consumption |

m³/cycle |

0.4-0.6 |

0.6-0.8 |

0.8-1 |

1-1.2 |

| Cooling Water Pressure |

Mpa |

0.4-0.6 |

0.4-0.6 |

0.4-0.6 |

0.4-0.6 |

| Drainage Vacuum Drain |

mm |

∅150 |

∅200 |

∅200 |

∅250 |

| Drainage Steam Vent |

mm |

∅200 |

∅200 |

∅200 |

∅200 |

| Drainage Condensate |

mm |

∅100 |

∅100 |

∅100 |

∅100 |

| Drainage Blower Outlet |

mm |

∅125 |

∅150 |

∅150 |

∅150 |

| Throughput |

15kg/m³ |

6min |

7min |

8min |

8min |

| Connected Load |

kw |

25 |

36 |

36 |

44 |

| Outside Dimension |

mm |

7200X4500X3000 |

11000X4500X3000 |

12600X3960X2906 |

15700X4600X3400 |

| Weight |

kg |

7200 |

12000 |

15000 |

18500 |

| Room Height Required |

mm |

6000 |

6000 |

6000 |

6000 |

FAQ

1. Where is your factory located?

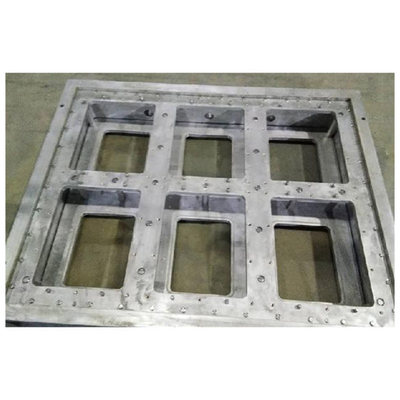

We have 2 production plant, one plant locates in Hangzhou which professionally producing EPS/EPP/ETPU machine. Another factory locates in Jiangsu Provide which producing EPS/EPP/ETPU mould. Both two factories are pretty close to the Shanghai port for easiest transportation.

2. Do you have detailed and professional installation manual?

We will provide very detailed installation manuals and videos, and the service until you are satisfied

3. Are you a trading company or a manufacturer?

We are manufacturer.

4. How long is your delivery time?

Normally delivery time is 30~45 days.

5. How many years have your company made this kind of equipment?

More than 10 years.

6. Can I only buy some spare parts from you?

Yes, we also provide all kinds of spare parts that relatives to our machine.

7. How do you pack the equipment?

We will strengthen and protect the equipment to ensure that they will not be damaged during transportation

8. Can you send your staff to install the equipment for us?

Under normal conditions, it is possible. Now it is an epidemic situation.

We will try our best to assist in case wecannot send technician in time. We will also conduct video connections with guests to teach them to install them in place.

9. Can you can design the equipment according to our size?

Yes, it is acceptable

10. How many production lines in your factory?

We have total 10 production line.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!