The EPS (Expanded Polystyrene) pre-expander machine is a device used in the manufacturing process of expanded polystyrene foam products.

Here is a detailed description of an EPS pre-expander machine:

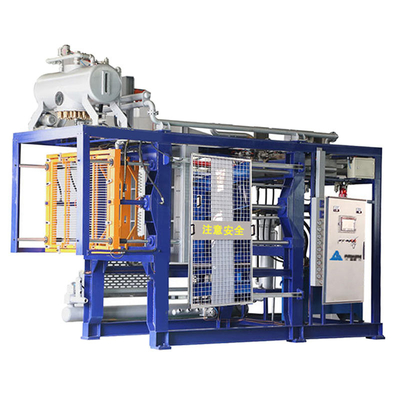

Hopper: The machine has a hopper where the raw polystyrene beads are loaded. The hopper feeds the beads into the pre-expanding chamber.

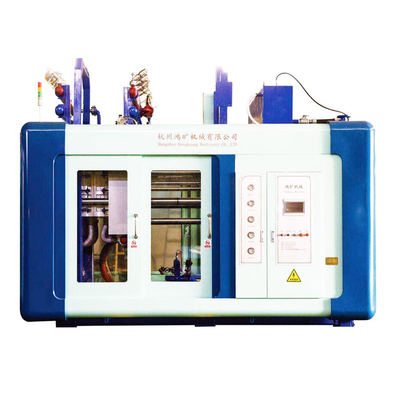

Pre-expanding chamber: The pre-expanding chamber is the main part of the machine where the actual expansion process takes place. The chamber is typically cylindrical and equipped with steam injection outlets. The polystyrene beads are introduced into the chamber, and steam is injected to heat and expand the beads.

Steam injection system: The pre-expander machine is equipped with a steam injection system that supplies steam into the pre-expanding chamber. The steam softens the polystyrene beads, causing them to expand.

Agitation system: Inside the pre-expanding chamber, there is an agitation system that ensures uniform heating and expansion of the beads. It usually consists of rotating arms or paddles that stir the beads while they are being exposed to steam.

Exhaust system: The pre-expander machine has an exhaust system to remove the steam and any volatile gases released during the expansion process. This system helps maintain a controlled and safe environment within the machine.

Control panel: The machine features a control panel that allows operators to monitor and adjust various parameters such as steam pressure, temperature, and expansion time. This ensures precise control over the expansion process and the quality of the expanded foam.

The EPS pre-expander machine is available in different sizes and capacities to accommodate various production requirements. Larger machines can handle higher volumes of beads and offer greater expansion capabilities.

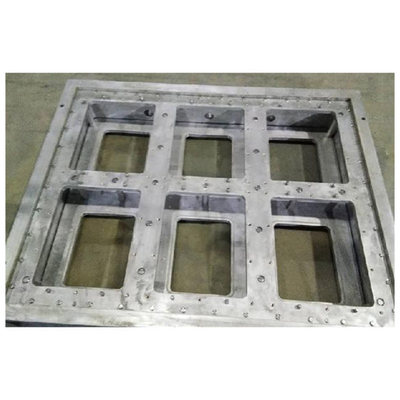

The pre-expanded beads produced by the machine are then transferred to a molding machine, where they are further processed into specific shapes such as blocks, sheets, or custom-molded products. The expanded polystyrene foam is widely used in packaging, insulation, construction, and other industries due to its lightweight, thermal insulation properties, and shock-absorbing qualities.

Please note that while the description above provides a general overview of an EPS pre-expander machine, specific machine designs and features may vary among manufacturers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!