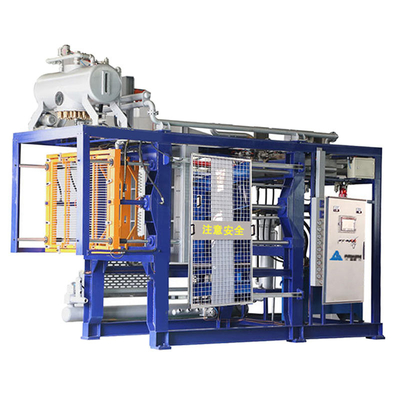

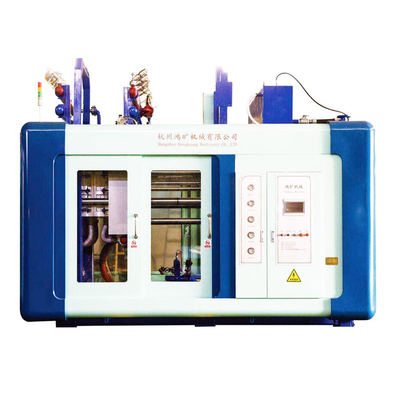

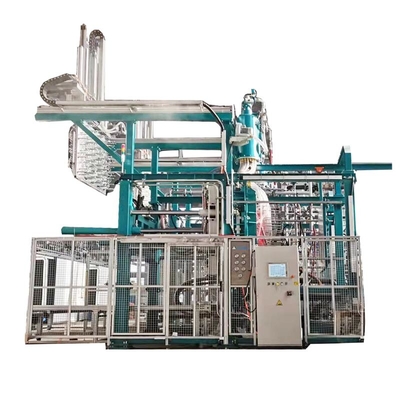

EPS Automatic Shape Moulding Machine With Robot

With mechanical hand forming machine, one-time palletizing, can be directly packed into bags with high efficiency; Less product damage, low defect rate; The latter process can be connected by automation.

1. The rack configuration with high strength improves the useful life of equipment by high annealing aging heat treatment,derusting by sandblast,galvanized surface and spraying heavy-duty paint on the surface.

2. Adopted with two-part light replaceable guide bushing and wearable selflubricating copper bushing to resolve the problem of difficulty to replace guide bushing of the equipment and improve the lubricating effect atthe same time .

| Item |

Unit |

PSSM160E |

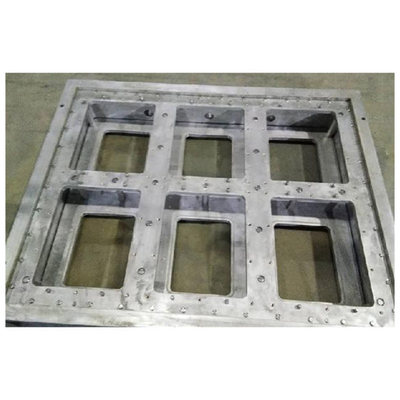

| Mould Dimension |

mm |

1600X1400 |

| Max Product Dimension |

mm |

1450X1350X350 |

| Stroke |

mm |

150-1500 |

| Steam Inlet |

mm |

DN100 |

| Steam Consumption |

t/t |

(7-11t)Steam of 1t Material |

| Cooling Water inlet |

mm |

DN80 |

Cooling Water

Consumption |

kg/cycle |

60-180 |

| Compressed Air Inlet |

mm |

DN40 |

Compressed Air

Consumption |

m³/cycle |

2 |

Vacuum Pump

Capacity |

m³/h |

230 |

| Drainage Port |

mm |

DN150 |

| Connected Load |

kw |

17 |

| Outside Dimension |

mm |

4600X2500X4000 |

| Weight |

kg |

6000 |

| Cycle Time |

s |

70-140 |

3. The hydraulic pressure System of the equipment is adopted with the design scheme of high speed and high pressure.The opening&clamping mold speed of conventional pumping unit is 150mm/s and the maximum opening&clamping mold speed of energy-saving machine can reach at 250mm/s.The automatic machine is adopted with clamping mode with two points each in both sides,which can clamp mold preferably to reduce leakage.

4. Technique application of pilot-operated steam valve:the valve is adopted with cylineder actuator of DN 80 to control large-diameter valve with accurate sensitive control.The input steam pressure stabilizes in 0.1-0.15Mpa with the error of±0.01Mpa.The heating time of the same type of equipment shortens by 30% and the energy consumption decreases by 25-30% on year -on year basis.

5. Technique application of efficient vacuum system:the equipment is adopted with large diameter Drainage pipe of 4-6 inch and long-distance condensing water pipe to increase the vacuum volume.It is equiped with demountable spray device on the top of the vacuum barrel to improve the vacuum condersing rate so as to increase the suction efficiency of the vacuum for reaching the cooling effect of taking water cooling as supplement and vacuum as the principal thing to make the water content of the produced product be less than or equal to 10% by spraying with cooling water .

FAQ

1. Where is your factory located?

We have 2 production plant, one plant locates in Hangzhou which professionally producing EPS/EPP/ETPU machine. Another factory locates in Jiangsu Provide which producing EPS/EPP/ETPU mould. Both two factories are pretty close to the Shanghai port for easiest transportation.

2. Do you have detailed and professional installation manual?

We will provide very detailed installation manuals and videos, and the service until you are satisfied

3. Are you a trading company or a manufacturer?

We are manufacturer.

4. How long is your delivery time?

Normally delivery time is 30~45 days.

5. How many years have your company made this kind of equipment?

More than 10 years.

6. Can I only buy some spare parts from you?

Yes, we also provide all kinds of spare parts that relatives to our machine.

7. How do you pack the equipment?

We will strengthen and protect the equipment to ensure that they will not be damaged during transportation

8. Can you send your staff to install the equipment for us?

Under normal conditions, it is possible. Now it is an epidemic situation.

We will try our best to assist in case wecannot send technician in time. We will also conduct video connections with guests to teach them to install them in place.

9. Can you can design the equipment according to our size?

Yes, it is acceptable

10. How many production lines in your factory?

We have total 10 production line.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!