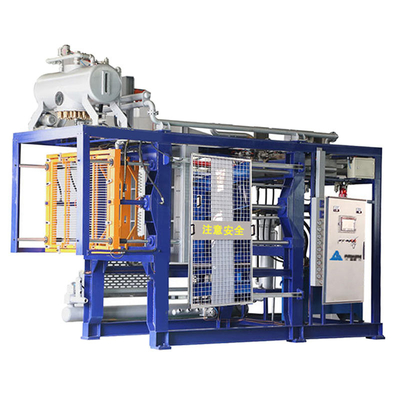

EPS (Expanded Polystyrene) shape moulding machine is a type of equipment used in the manufacturing process of EPS foam products. EPS foam, also known as Styrofoam, is a lightweight and versatile material widely used for insulation, packaging, and construction applications.

The shape moulding machine is specifically designed to produce various shapes and sizes of EPS foam products, such as blocks, sheets, panels, and custom molded products. It uses steam and pressure to expand and mold the EPS beads into the desired shape.

Here's a general overview of how an EPS shape moulding machine works:

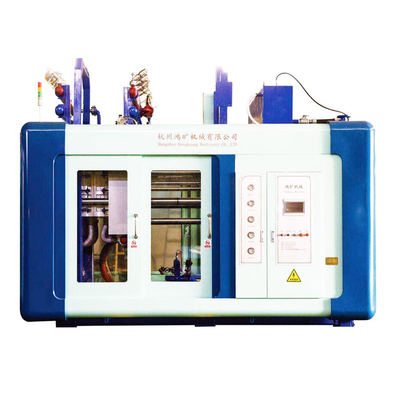

Pre-expansion: The process begins with the pre-expansion of EPS beads. The beads are fed into a pre-expander, where they are exposed to steam and heat. The heat causes the beads to expand and fuse together, forming expanded beads with low density.

Aging: The expanded beads are then transferred to an aging silo, where they are allowed to cool and stabilize for a certain period. This aging process helps to improve the performance and consistency of the EPS foam.

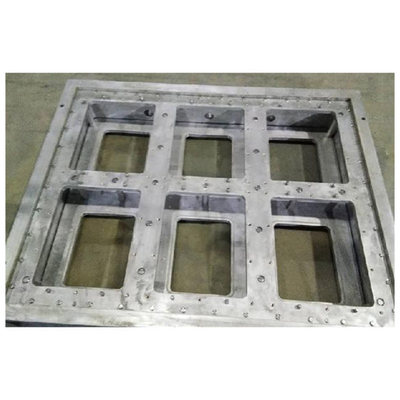

Molding: The aged beads are then fed into the shape moulding machine. The machine consists of a mold cavity in the desired shape and size of the finished product. The beads are evenly distributed within the mold cavity.

Steam and pressure application: Once the mold is filled with the expanded beads, steam is injected into the mold cavity. The steam causes the beads to further expand and fuse together, conforming to the shape of the mold. Simultaneously, controlled pressure is applied to ensure proper density and dimensional stability of the final product.

Cooling and demolding: After the desired molding time, the steam supply is stopped, and the mold is cooled using either water or air. The cooling process solidifies the expanded beads into a solid foam shape. Once cooled, the mold opens, and the finished product is ejected.

EPS shape moulding machines are available in different sizes and configurations to accommodate various production capacities and product requirements. They can be operated manually or automatically, depending on the complexity and level of automation.

These machines offer several advantages, including high production efficiency, precise molding control, energy efficiency, and the ability to produce lightweight and durable EPS foam products with excellent thermal insulation properties.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!